Bull Nose End Mill Definition

The teeth can be straight or helical. Ball end mills, also known as ball nose end mills, are used for milling contoured surfaces, slotting and pocketing.

In end milling, the cutter generally rotates on an axis vertical to the workpiece.

Bull nose end mill definition. Our end mills can be used in a broad spectrum of materials such as hardened steels, soft steels, A ball nose end mill, also known as a spherical end mill or ball end mill, has a semisphere at the tool end. What is a bull nose end mill?

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. A corner radius end mill , also called a bull nose or torus end mill , is a rotary cutting tool with multiple edges used in machining applications, producing a radius in the corner of a slot or pocket in a workpiece. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder.

These have a flat bottom, but rounded corners, so you can have a filleted inner corner while also avoiding the problem of scalloping. Straight and helical ball end mills are widely used in machining sculptured die and aerospace part surfaces, and bull nosed cutters produce periphery of parts meeting with the bottom floor with fillets. Most end mills are manufactured from.

Should i use carbide end mills or hss end mills? Moulds, dies and blades milling are usual examples of this category. They are used to create a fillet on the bottom of a wall.

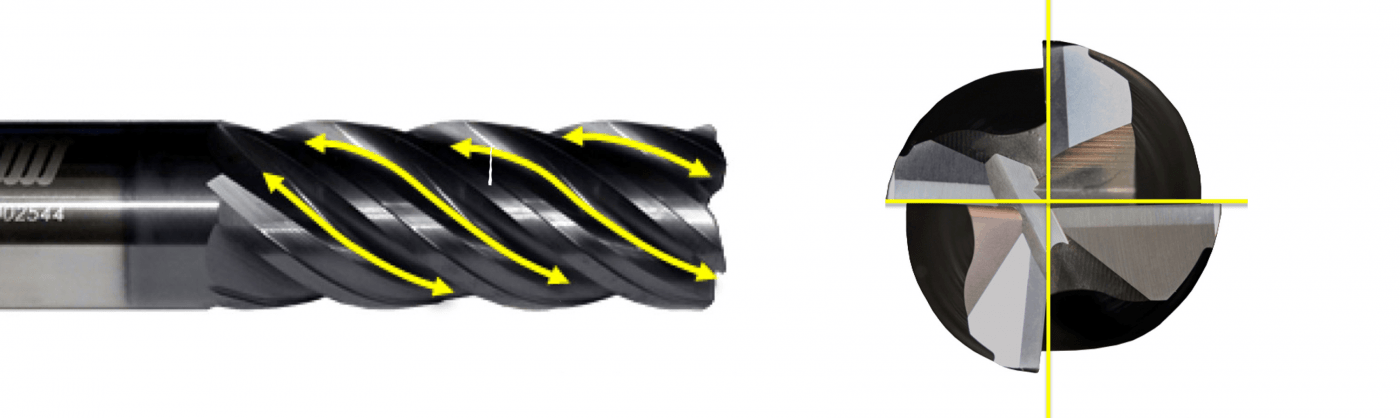

Variable index (pitch) end mills. This type of tooling features flutes with no flat bottom, rounded off at the end creating a “ball nose” at the tip of the tool. Similar to square end mills/flat end mills but these have a round cutting edge also known as bull nose (not to be confused with ball nose as mentioned above).

These mills also use eccentric grinding on the diameters of the mills to give them strenth and stability. Ball nose milling without a tilt angle. Variable spacing between the flutes reduces vibration, allowing these end mills to provide fast cuts, smooth finishes, and long tool life.

Because they are sturdier than an end mill they are also sometimes used for roughing operations. The cutter diameter is often the first thing machinists look for when choosing a tool for their job. Bull nose end mills have a radius corner.

Cutting teeth are located on both the end face of the cutter and the periphery of the cutter body. While a drill bit can only cut in the axial direction, most milling bits can cut in the radial direction. End mills can be classified based upon:

End mills are used in milling. Ball nose mills are used for 3d milling. Today's high performance end mills utilize variable index and/or variable flute designs to yield the maximum metal removal rates possible.

Our impressive lineup features a large selection of high feed solid carbide end mills that achieve the highest performance in the industry. An end mill is a type of milling cutter, a cutting tool used in industrial milling applications. It is distinguished from the drill bit in its application, geometry, and manufacture.

So i don't know if its a problem with the pass or the tool definition to make that work. Ball nose end mills are used on workpieces with complex. The words end mill are generally used to refer to flat bottomed cutters, but also include rounded cutters (referred to as ball nosed ) and radiused cutters (referred to.

Tapered helical end mills are used in five axis machining of jet Corner radius end mill cutters have a stronger milling edge than square end mills, so feed rates may be increased and yield longer tool life and. I have some ball end mills that i hardly ever use.

A tool with larger radii can also be referred to as “bull nose.” ball profile end mills. In the meantime @tbaker the only compromise is to define it as a bullnose, with the chord length of the bull radius matching the chamfer length. The hygears 5axis cnc interface

A ball end mill is not the same as a corner radius/bull nose end mill. The ball has a radius with it's center point at the center of the end mill, so the radius is always 1/2 of the diameter. Simple cylindrical helical end mills are used in peripheral milling of prismatic parts.

Not all mills can cut axially; End mills (middle row in image) are those tools that have cutting teeth at one end, as well as on the sides. A corner radius end mill has a small radius on each corner, the radius is typically.020,.030,.045, etc.

End mills can be used on vertical and horizontal milling machines for a variety of facing, slotting, and profiling operations. Those designed to cut axially are known as end mills. They are less prone to chipping and generally have a longer tool life.

Millstar offers a wide variety of solid carbide end mills that are designed for high performance machining. Bull nose end mills (corner radius) bull end mills are simply corner radius end mill cutters.

0 Response to "Bull Nose End Mill Definition"

Posting Komentar